Exposed

MoreldAqua dives deep

We are among the country’s most experienced experts in exposed aquaculture

Moreld Aqua has embarked on a dynamic and enlightening journey in recent years. Our expertise as design and structural specialists for offshore installations has undergone a significant transformation over the past decade, making us a global leader in marine design for open-sea aquaculture.

Our customers have entrusted us with insights into their various approaches to exposed and semi-exposed aquaculture. This has uniquely positioned Moreld Aqua with unparalleled expertise. We’ve been fortunate to harness the best minds from the sea to address the well-known challenges associated with offshore aquaculture.

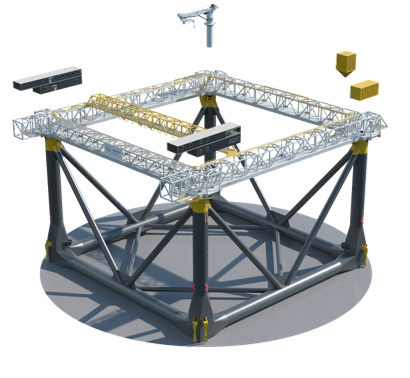

We take pride in this and can now introduce our own design, which we believe is tailored to meet the future of semi exposed and open-sea aquaculture. GM Aqua design is created by Global Maritime and possesses the X-factor our customers are seeking.

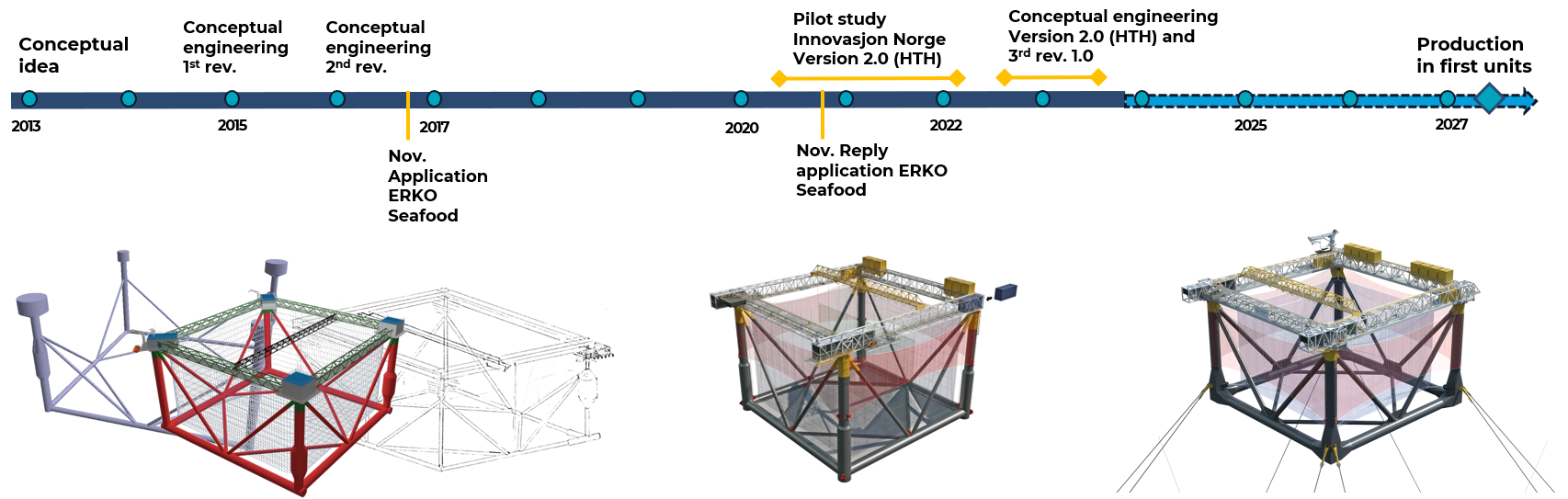

Development timeline and completed engineering work

GM Aqua Design started as a concept idea in 2013. Since then, the design has been fine-tuned and adapted into two variations: one for exposed areas and another fully exposed for offshore locations. Several in-depth area and location studies have been conducted to tailor the design to ensure optimal performance in each specific environment.

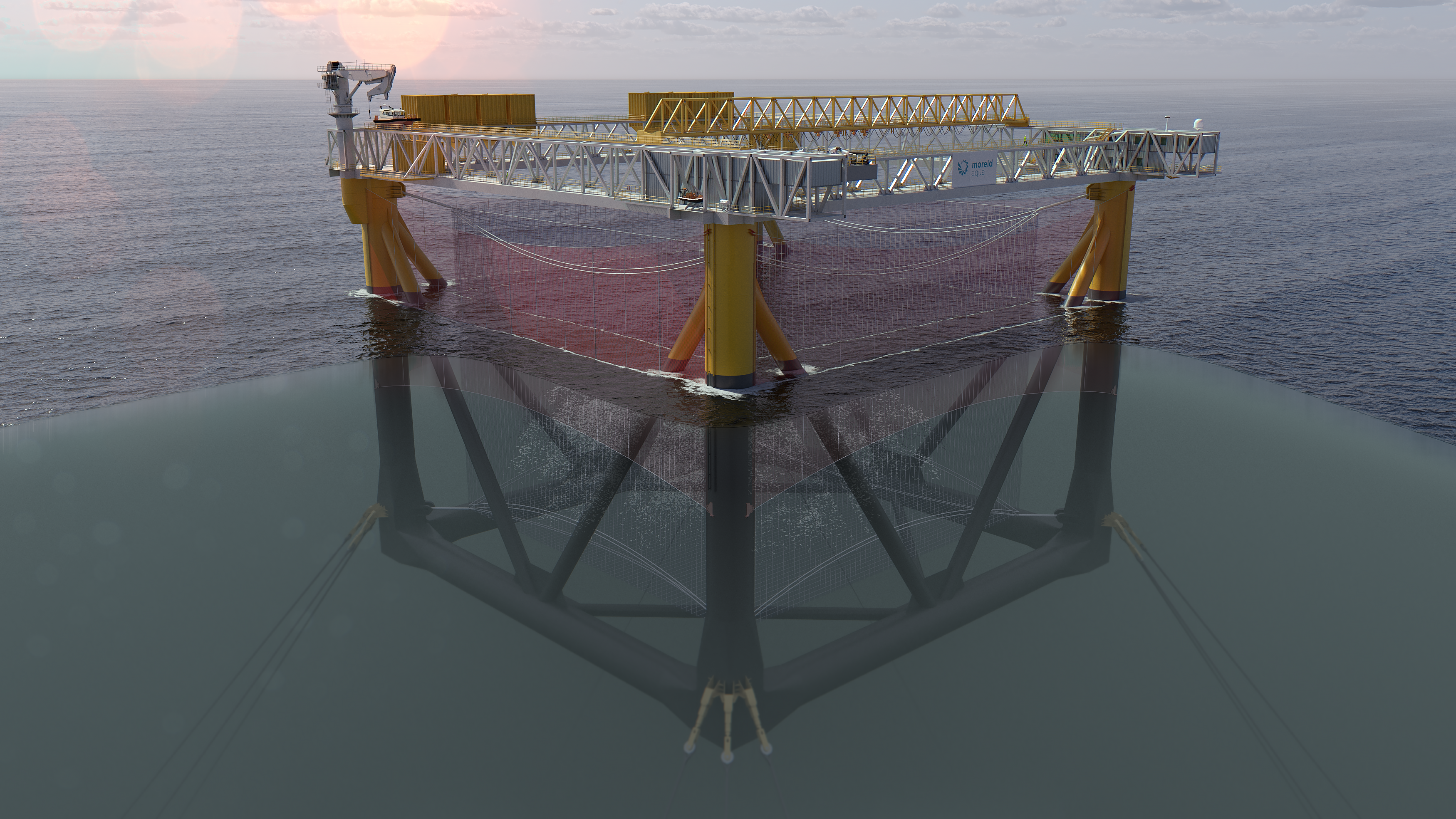

Technical Details:

Dimensions: 100m x 100m c/c columns

Height : 65 m

Volume : 288.000 m3 → 300.000+ m3

Weight main steel: 6.500 mT

Operational Data:

Permanently moored at location

100-450m water depth

Hs 7-8m (sheltered location)

Displacement: 24.450 mT

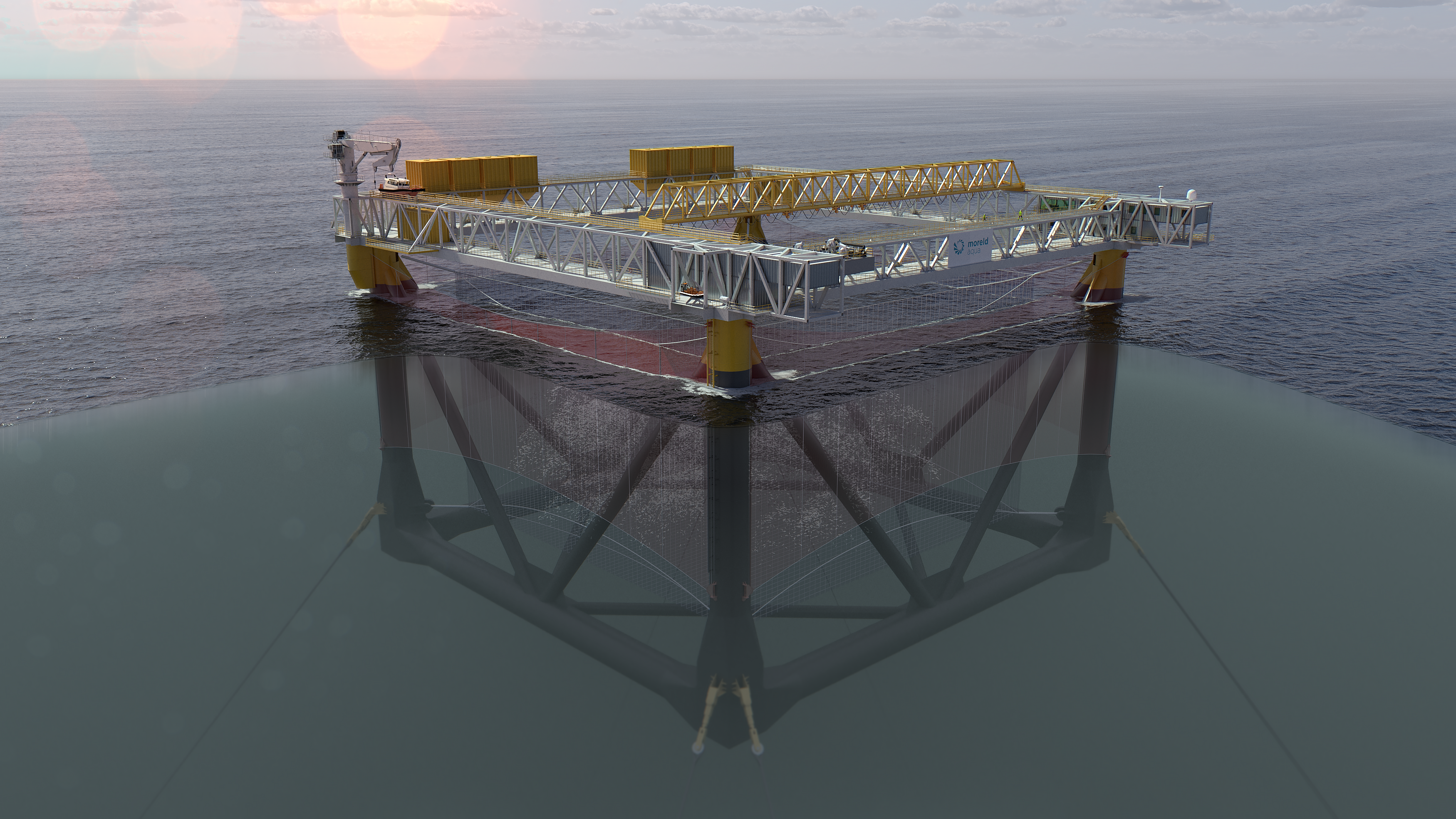

GM Aqua Design 1.0 – Semi exposed

Technical Details:

Dimensions: 100m x 100m c/c columns

Height : 78 m

Volume : 288.000 m3 → 300.000+ m3

Weight main steel: 9.400 mT

Operational Data:

Permanently moored at location

100-450m water depth

Hs 17.3m (sheltered location)

Displacement: 30.190 mT

GM Aqua Design 2.0 – Open sea

Key elements

Low steel weight: Unrivalled pen volume to steel ratio of 21-31 kg/m3, reducing steel sourcing costs (key capex element)

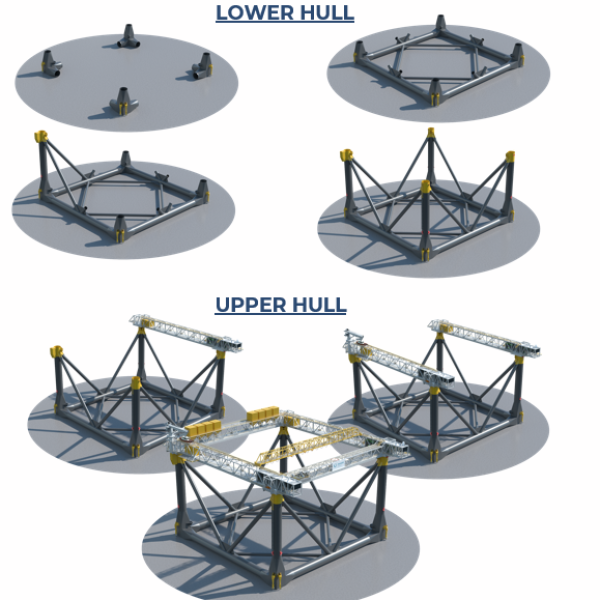

Optimal assembly: Modularity of units allows for various assembly routes, lowering construction and transportation costs

Flexible outfitting: Topside structure and ballast system designed to allow for myriads of outfitting options (# of cranes etc.)

Construction and assembly:

Units suited for typical dry dock, slip dock and on-land construction solution with a submersible barge for launch

The on-land construction opens for more yards

Larger elements can be prefabricated (at preferred site) and assembled at site with right quayside facility

Submersible barge at quay, onloading by a skidding or trailer-on operation and launched in sheltered water

Upper Hull mating by floatover or lift on sea can be used to reduce work at height -> launch of assembled Lower Hull separately

Final assembly, mechanical completion, sea trail etc. in sheltered water

Transport and site:

Float on to Heavy Transport Vessel (HTV) or barge and transported to sheltered water near to site

Hookup and wet tow to site and installation in pre-laid mooring spread

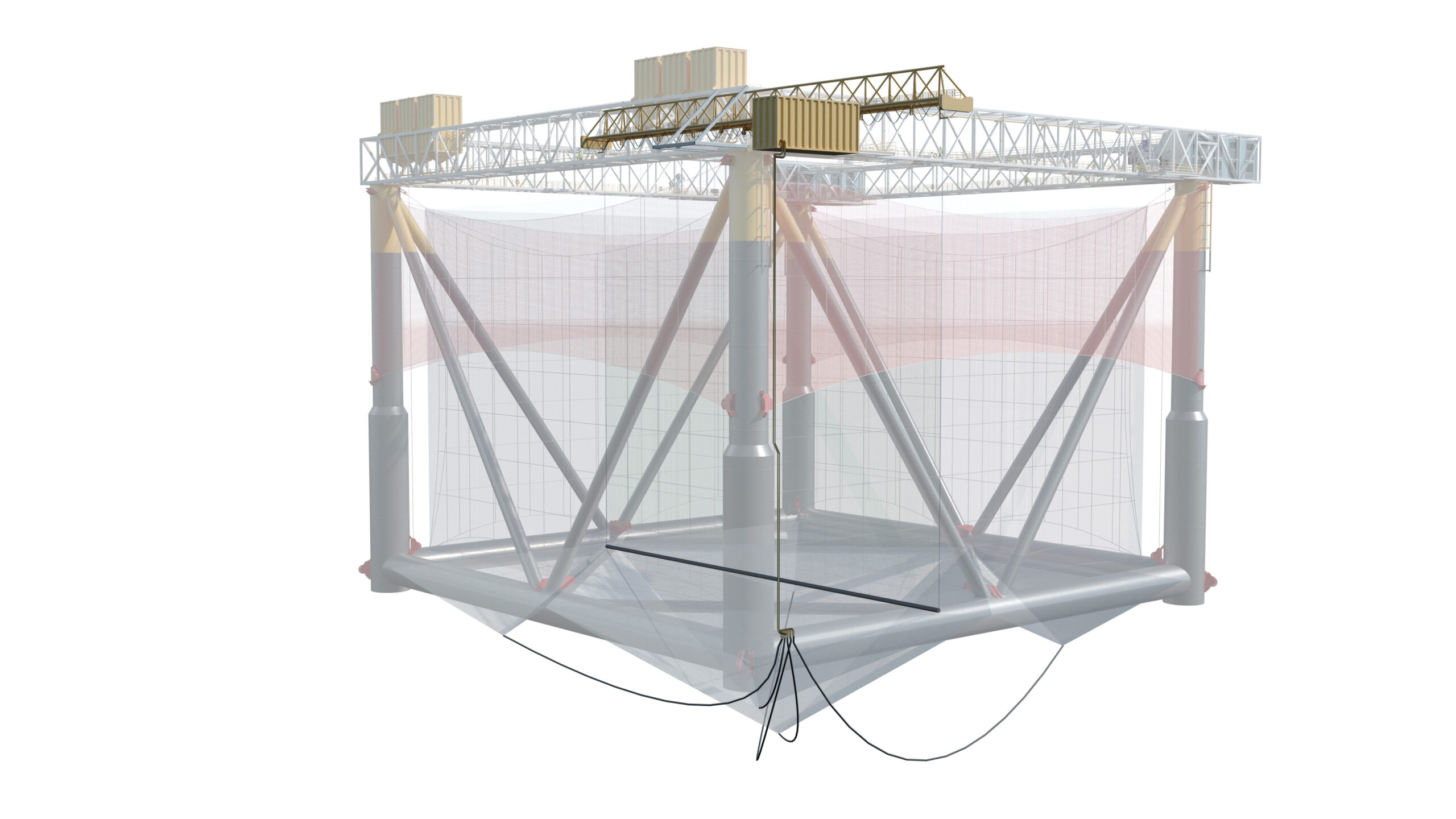

Generic design

Site specific analysis and criteria’s

Summer April to September

Winter October to Marsh

Site specific operation and airgap analysis

Achieve season variation in draft conditions

Strategy split summer and winter:

The draft condition will influence fish habitat size

Optimize habitat size

Fish farmer to utilize the full production potential

Do you want to learn more about your options for engaging in exposed aquaculture?

Get in touch with Arne! He is one of the country’s leading experts in exposed aquaculture

Arne Vagle

mail: arne.vagle@moreldaqua.com

mob: 930 53 802